Fully Automatic Hot Knife Water-Base Film Laminating Machine

Overview Product Description Basic Configuration: 1.High speed feeder: Eight suction nozzles achieve high speed and high

Basic Info

| Model NO. | RFM-106SC |

| After-sales Service | One year |

| Warranty | One year |

| Classification | Post-Coating Laminating Machine |

| Application | Packaging Paper, Film Material, Soft Board |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Membrane Material | Matt Film |

| Plastic Film Mulching Modes | Hot Laminating |

| Performance | Waterproof |

| Max. Sheet Size | 1060*800mm |

| Min. Sheet Size | 300*300mm |

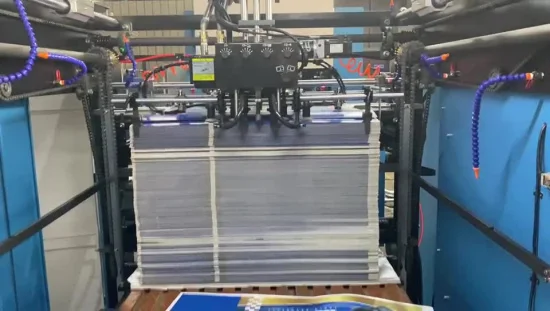

| Feeder Piling Height | 1300mm |

| Stacker Piling Height | 1060mm |

| Total Power | 101kw |

| Production Speed | 10-80m/Min |

| Weight | 9000kgs |

| Transport Package | Wooden Case+Pallet |

| Specification | 9855*2380*3000mm 101kg |

| Trademark | Tiancen |

| Origin | Shanghai China |

Product Description

Basic Configuration:

1.High speed feeder: Eight suction nozzles achieve high speed and high precision, Standard configuration with pre-pile unit 2.Powder removing: double sets of hot pressing roller powder remove), it is not necessary to maintain specially and clean inner, keeping powder removing effect in a long time. 3.Glue Coating and pressure roller: The machine has two sets of separate circulating temperature controller beside the laminator. Main pressure steel roller is heated by oil out of the machine. So the temperature in roller is uniform and accurate. 800mm diameter oil circulating heating glue drying roller, 380mm diameter Oil circulating heating main pressing steel roller, Ceramic anilox roller coating glue, Inovance PLC, Rexroth Frequency converter 4.Product sheet cutting methods: Use hot knife to cut film, it is suitable for PET/OPP film and every kinds of metal film, after that the products will be separated by shearing device, all the processes make your products perfectly. Hot knife to cut film, Suitable for PET film, Make products perfectly. 5.Stacker: Non-stop delivery switching device, during high speed running can turn on superposed mode matched with wave pressed device make delivery smoothly. 6.Advantage of equipment: It is suitable for water-based glue, oil-based glue, non-glue film and thermal film. showed in human-computer interface.Detailed PhotosAutomatic feeder Shaftless servo Feeder, Feeder CNC automatic positioning.

High speed feeder, Max. feeding speed 12,000 sheets/h, eight suction nozzles achieve high speed and high precision.

Sheets Front guide and sheets drawing control guide with servo technology make overlap during ±2mm in high speed running.Hot pressing powder removing roller, use chrome plating surface treatment steel roller, the effect of powder removing is guaranteed, and can flat rough paper. Heating the mirror roller automatic constant, can maintain the set temperature and with stable effect of powder removing.

Product Parameters

| Main technical parameters | RFM106SC, HOT KNIFE |

| Max. sheet size | W1060×L800mm |

| Min. sheet size | W300×L300mm |

| Max. mechanical speed | 100m/min, 11000sheets/hour |

| Laminating speed | 20-100m/min |

| Paper thickness | 105-500gsm |

| Piling height | 1300mm |

| Stacker piling height | 1300mm |

| Total power | 70kW (380V, AC3φ, 50Hz) (normal working power: 28-38kW) |

| Overall dimension | L 9850 × W 2380 × H 3000 mm |

Our highly skilled engineers take pride in producing top of the line machinery that is world renowned for its quality, reliability, and productivity. Highly active in R&D, Shanghai Tiancen Machinery Manufacture continually expands into new technologies and applications including:

Film Laminating Machines Ink Jet Spot UV / 3D Spot UV & Foiling Ink Jet digital printer for code/Bar code/ QR code Roller Coat UV varnish coater Playing card cut, collate machine

We manufacture in Shanghai, China, an area recognized as the China's science and technology, trade, information, finance and shipping centers. Our machinery is built by skilled engineers. We utilize top quality components. This quality in manufacturing allows our customers to produce higher quality print with a greater perceived value. Our machinery is designed to with very little down time or regular maintenance requirements, saving our customers invaluable time and financial resources. We manufacture machinery with exceptional productivity, which often reduce labor costs and provide a very quick return on investment.

Send to us